ROCKEATER TOOL CARE GUIDE

Taking Care of your tool bit will give you longer tool life. It's important to use the correct grease and grease your Hammer correctly. Please see section "Lubrication guide for tool bits".

Taking care of you hammer will give you longer hammer life also longer tool life and save you money. The condition of your hammer affects the life of your tool bit.

Make sure your hammer oil flows, pressures and relief cartridge cracking pressure are set correctly as per Manufacturers recommended Specs.

1. Maintain Hammer buffers so that hammer is snug and not loose in its outer casing.

2. Maintain correct nitrogen pressure in accumulators.

3. Maintain correct nitrogen pressure in back head accumulator.

4. Only use specially formulated Rockeater Hammer grease or an equivalent. Where auto lube is installed make sure grease supply hoses are not kinked and that the auto lube delivery is correctly set.

5. Maintain case liners to make sure hammer power cell is snug in case and not shaking around loose.

6. Replace impact rings and buffer rings as soon as they are worn so that tools sit snuggly in its seating.

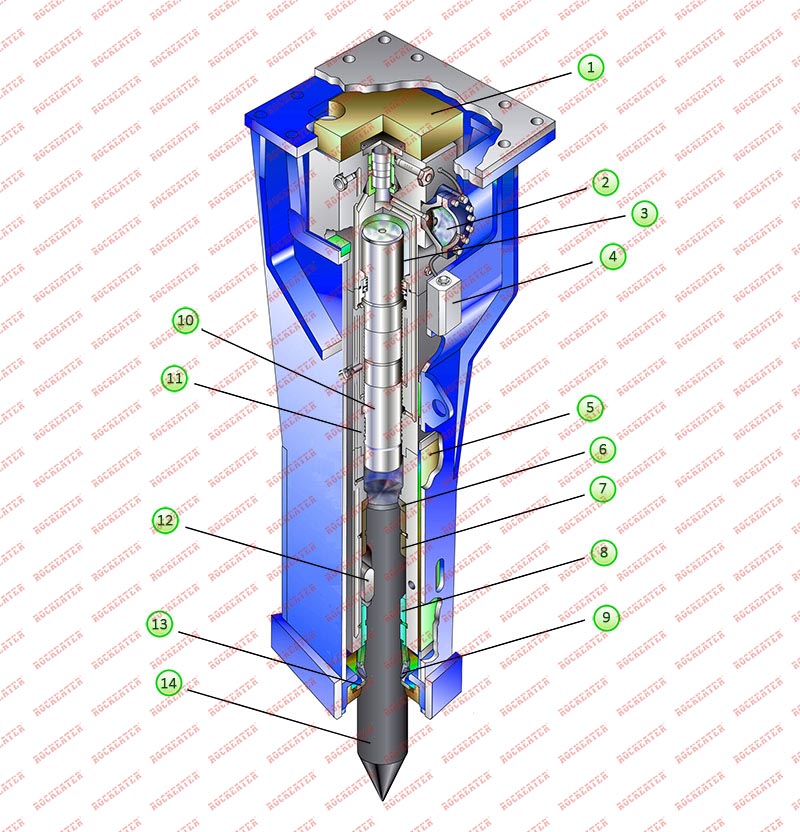

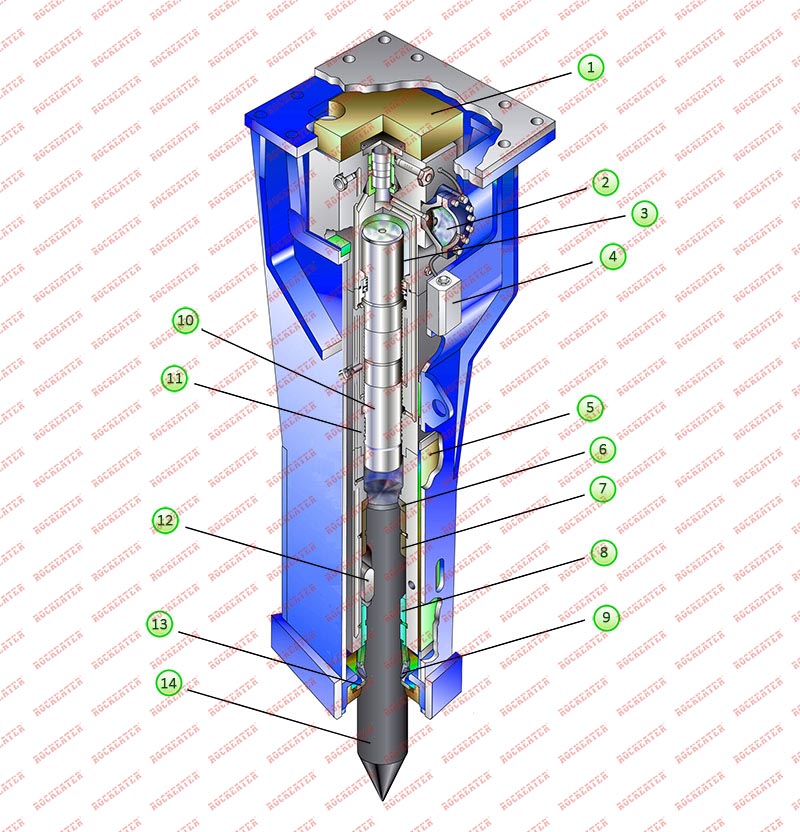

7. Replace upper bushes when worn so that tool slides snuggly. This will protect hammer piston No 10, Cylinder No 11 as well as your Rockeater tool No 14.

8. Replace lower bushes when worn so that tool slides snuggly. This will protect hammer piston No 10, Cylinder No 11 as well as your Rockeater tool No 14.

9. Maintain dust seals this will protect your hammer and reduce stress raisers on tool bit no 14.

10. Protect your piston by using a good quality tool bit No 12. Poor quality tools and tools that are too hard cause damage to buffer rings No 6, upper bushing no 7, lower bushing no 8, tool retainers no 12 and worst of all can cause piston face to chip no 10. Chipping can cause sever damage to piston wall no 10 and cylinder no 11. This can prove to be very costly.

11. Protect cylinder by maintaining bushes no 7 and no 8.

12. Maintain tool retainer pins (bars), Grind off any burrs and replace as soon as wear shows.

13. Maintain scraper seals this will help reduce stress raisers on tool no 14 and extend tool life.

14. Using a good quality tool will give you longer tool life and prevent damage to the hammers internal parts. A tool that is too soft will not perform its duties. A tool that is too hard will have a greater tendency to break. A tool that is too long will also have a greater tendency to break.